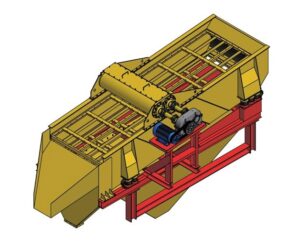

Vibrating Screen

Vibrating Screens are used for ore dressing processes and separating materials in sand mines. Undoubtedly, they could be used in other occupations, as well. Screens are made in different length and width and they usually have one, two, three or four stories. However, according to customers order, screens will have more stories.

.JPG)

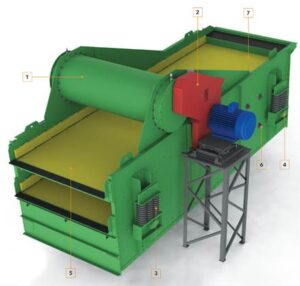

Features:

Having special design, vibrating screens vibrate all nets but it will not affect the chassis. These screens do not need to be serviced all the time but the only required action is greasing.

-

-

- High resistant structure

- High-quality frames made from layers

- Designed shafts, made from steel

- Equipped system for valve grinding

- Double – bearing system to increase resistance

- Stories made from iron to avoid breaking

- Standard slope, suitable for the process of ore dressing (It is more useful in comparison with other produced system)

- Gadgets are fixed in two ways: Vaskazyni & Greasy

-

The vibration system of these helmets is fitted with one or two anchor axles and adjustable weights and is mounted on very strong bearings against moisture and dust that transmits circular vibrations of body shape to special spiral springs, body The main is made of solid steel and has a good ability to install grids that are made to increase the separation percentage in aggregates.

Vibrating screen features:

-

- Strong building and high strength

- Bodies made of seamless sheets of weld

- Replaceable cast iron weights for adjusting the vibration range

- Shafts made of alloy steel

- Complete lubrication system and use of sealing devices

- Double roller barrels for rotational motion

- Quick and easy installation and replacement of grille using a crepe

- Cylinders made from a manisman tube to reduce load and prevent failur