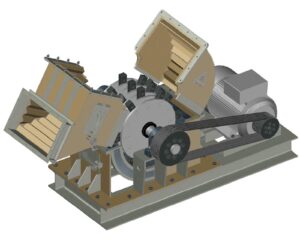

Samen Industrial Group Hammer Mill

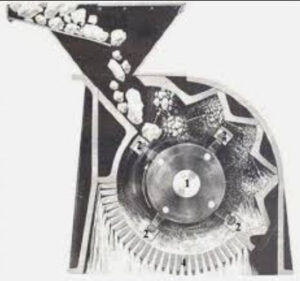

The Hammer Mill or Impact Grinder is a device used to crush various types of minerals such as gypsum, silica, feldspar, salt, barite, dolomite, construction stones, etc. The grinding material used to grind high hardness materials is used to increase the life of the body and rotor of the machine. To prevent dust exhaust from the sides of the shaft, the outlet of the device is used in the ablation system. In the new design, the hammer mill and even the disc are easily interchangeable. The load output is adjustable from 5 to 25 mm for order.

Hammers are the most important part of the mill and do the rotation of the blade for crushing or flourishing. The hammer mill is divided into various groups based on the propulsion, production, or mechanism.

This machine produces a capacity of 5 to 30 tons per hour with anti-wear material as standard. The mill’s body is from 10 to 15 mm thick steel sheets.

The number of steel hammer shafts varies from 20 to 60 depending on the model, as well as on customer’s request.

The Hammer Mill or Impact Grinder is a device used to crush various types of minerals such as gypsum, silica, feldspar, salt, barite, dolomite, construction stones, etc. The grinding material used to grind high hardness materials is used to increase the life of the body and rotor of the machine. To prevent dust exhaust from the sides of the shaft, the outlet of the device is used in the ablation system. In the new design, the hammer mill and even the disc are easily interchangeable. The load output is adjustable from 5 to 25 mm for order.

Technical Information

| Model | Number of Hammers | Rotor (mm) | Length of rotor (mm) | Required Power (KW) | Capacity (t/h) |

|---|---|---|---|---|---|

| 202 | 16 | 660 | 490 | 37 | 5-8 |

| 203 | 20 | 660 | 590 | 45 | 8-10 |

| 204 | 24 | 700 | 720 | 55 | 14-16 |

| 205A | 36 | 800 | 720 | 75 | 18-22 |

| 205B | 36 | 900 | 720 | 75-90 | 24-28 |

| 205C | 36 | 1000 | 720 | 90 | 30-35 |

| 206 | 42 | 1000 | 820 | 90-110 | 45-55 |