Samen Group Sand Maker

Sandstones are used in mines which tend to produce more broken sand, with various capacities available for crushing non-sticky dry materials up to 450MP, such as quartz, basalt, lime, and granite. .. Other mineral stones are made and produced in two types of envelopes and rabbits.

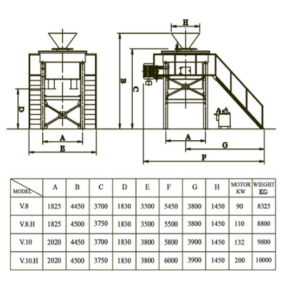

These sandstones have a hammer structure and their grinding operations are done around the vertical axis. The input capacity of the machine is 25 and 40 tons per hour, and 80-75% of the output is sandy 8-0 mm; the grain produced will be round and broken. The device has three side doors, and with an opening, all internal parts are available, and as a result, they can be easily replaced.

-

- There are two different types of Sand Makers:

The rabbit sand maker

The rabbit sand maker is another kind of sandblasting machine, with its hammer axes vertical and also known as the vertical shaft. In fact, it can be said hammer crusher is a kind of hammer with a vertical shaft. On the shaft of this rotor, the crusher is located on which places to install the hammer crusher is installed. The rocks are attacked by these springs and thrown to the inside of the body.

The production capacity of this type is 25-30 tons per hour, which is about 70% of the mass production of 0-6 and suitable filter.

The entrance is 2.5 cm and has 3 side doors, which makes it easy to repair.

Technical Information

-

-

- Engine power: 75 hp

- Weight: 410kg

- Capacity: 25 t/h

- Inner stone size: 20 to 50 mm

- Output Size: 0 mm and 10 mm

-

Features:

-

- Replacing parts in minimum time

- No vibration performance with special bumpers

- Install and install the device conveniently

- It has three side doors for easy service

- Hammers made of Manganese Steel

- Antifreeze scent container

The Rock&Rock Sand Maker

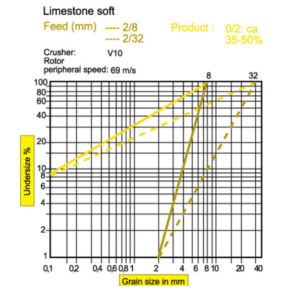

Vertical sandstone or rock and roll are sandblasting type. In this type of sandstone, rubble collides, crush and crush into the sand. The high capacity of sand production is one of the highlights of this device.

This machine is used for crushing aggregates 6 to 30 mm. The product of this machine is 0 to 6 mm at around 25 to 30 tons per hour in ideal conditions. Producing the product on this machine is by rotating high-speed rotating hammer blades around the vertical axis.

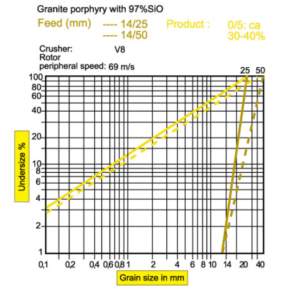

It is used as a secondary crusher, which has the ability to generate combined loads in a multifaceted manner in accordance with the latest standards for the production of sand for use in asphalt and concrete. Also rock and rock crusher in crushing hard gems such as feldspar, silica, dolomite, barite, and so on. The grinding system of the centrifuge sand mixer is self-propelled.

It should be noted that all the rock and rock hammer mills are made of tungsten, and the rotor, which is the most important part of this machine, is made from Hardox 400.

Features and advantages:

- High percentage of materials below 5 mm

- Lifetime of the parts due to their low wear

- Easy replacement of parts in minimal time

- No vibration performance with special bumpers

- Capacity 50 to 140 tons per hour

- Special vibration shields to prevent vibration

- Easy installation