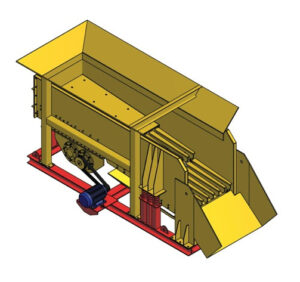

Samen Industrial Group Sand & Gravel Feeder

Feeders are generally situated at the primary end of the processing facility, requiring rugged design in order to handle the impact of the material being fed from front end loaders, excavators, etc. the feeder moves material to the crushing and screening equipment in a controlled fashion. Machine Roll Feeders can be used with silos, for direct feeding of aggregate into crushers or onto conveyors; additionally they can be used for secondary or tertiary crushers to eliminate surges and ensure a constant feed is maintained. Machine Roll produces feeders in three varieties consisting of reciprocating feeders, vibrating feeders and belt feeders. Additionally they are engineered to be completely interchangeable so as to provide the operators current and future needs.

Our reciprocating feeders are ideally suited for moist materials and provide continuous feed rates under a variety of materials and loading conditions.

Feeder used in mountains:

This type of feeder is installed before grizzly screen in mines located in mountains. This way, the pressure of materials on the screen or other systems will be reduced.

-

- We Produce two different kindes of feeders

Single Axis Feeders

Vibrating feeders are located at the beginning of crushing lines and designed and constructed for use in difficult conditions and long operating times for continuous crushing operations.

These machines are used by silos of various capacities to feed and direct the materials and materials into the crusher.

The bearings selected on this machine are used in hard conditions. Also, the use of double barrel roller brushes has been in line with these conditions and has been controlling rotational movement.

Good and uniform transmission, heavy load bearing and off-center movement are the specifications of this device.

This machine, with its smooth and uniform movements, due to the design and construction of the vibration axis out of the center, is transmitted to the crusher by a linear movement of raw material.

-

- Single axle gravel feeder, which has different types:

- 120 in 3 meters

- 120 by 4 meters

- 140 in 3 meters

- 140 in 4 meters

- Single axle grooved feeder

- Single axle grooved feeder

This feeder is manufactured with very high and adjustable up to 250 tons per hour

- Single axle gravel feeder, which has different types:

Double Axis Feeders

The Double Axis Feeder is systematically designed to carry out line feed operations, and has a output valve adjustment capability to control the dimensions of the final product and is suitable for lines with fine and fine grains.

Double Axis feeder features

-

- Adjustable vibration range

- Suitable replacement for chain feeders and shaft feeders in large cement factories and mines.

- Strong structure and high strength

- It has a grooved system at the outlet side for increased capacity.

- Shafts made of alloy steel

- High capacity silo

- Suitable for separating the mixture of stones

- A vibration range adjustment system for determining load capacity by two lame steel shafts

- Complete lubrication system and use of sealing devices

- Use of anti-wear steel sheets in the body and trays of the floor

- Use double roller barrels for rotational movement